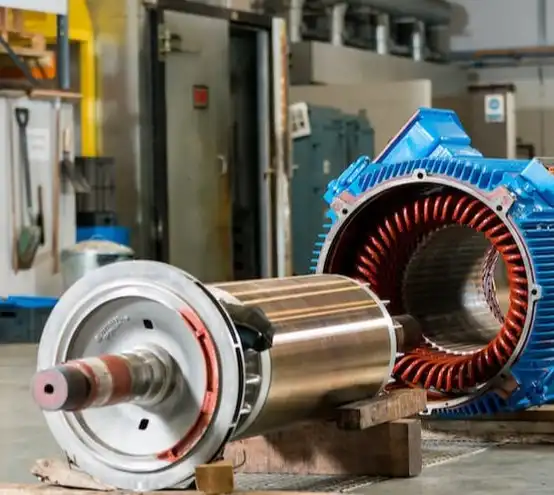

Maintenance Solutions:

At Motocoil, we offer both online and offline maintenance solutions. We offer operational inspections and static inspections to AC/DC units to ensure they perform at their peak majority of the time. All our successful inspections services involevs detailed visual inspection and data capturing with comprehensive notes and photography.

Our AC/DC motor inspection routines involves:

- Visual Inspections

- Bearing and Lubrication Inspections

- Vibration Assessment

- Motor Internal Assessment (Winding, Insulation, Power Sypply, Leads, Commutators, Brushes etc.)

- Heat Assessment with Infrared Thermography

- Technical Reporting

During our routine checks we record all findings and subsequently compile a comprehensive technical report with actionable recommendations that needs to be actioned to ensure the motor is well maintained to perform at its peak.